| Weight | N/A |

|---|

- Sorry, this product cannot be purchased.

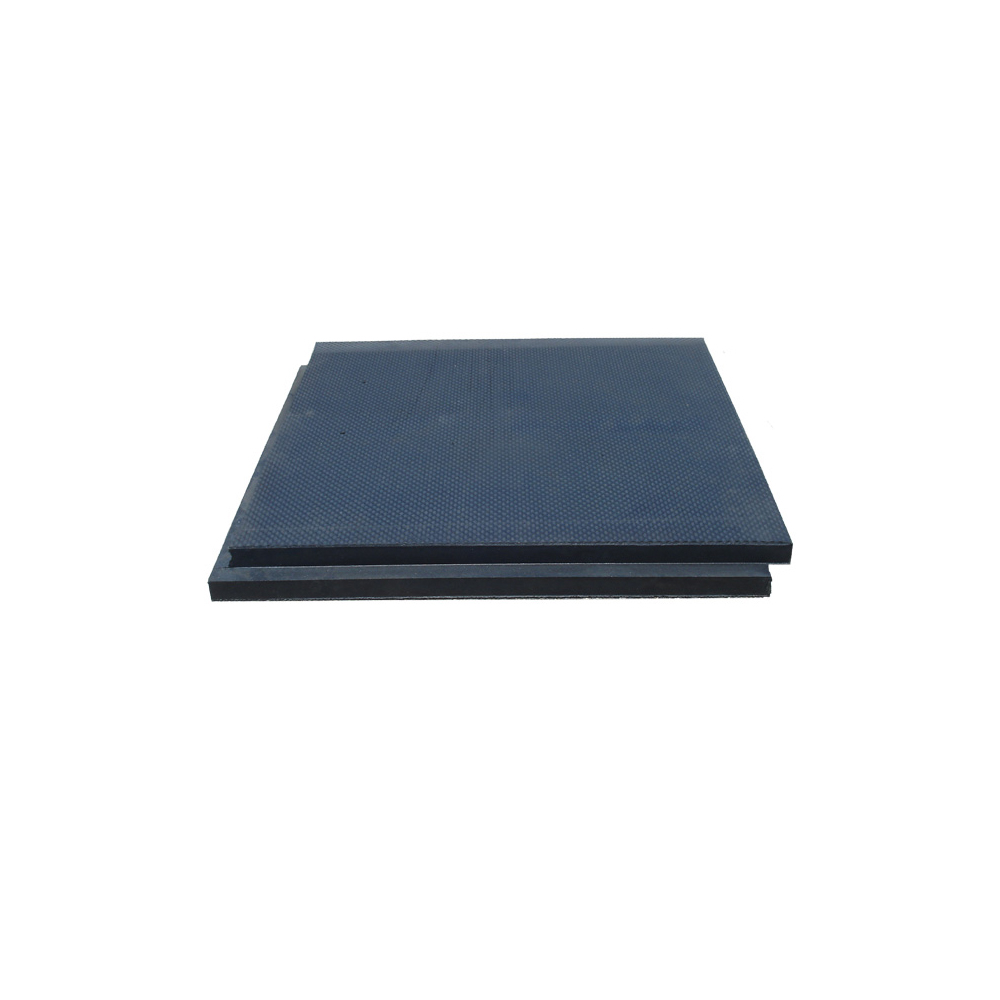

Ballistic Rubber Panels

$19.95 – $1,495.00

Our ballistic rubber panels are used in our bullet traps as replacement panels or mounted to existing armor steel plate (or concrete walls) for significant reduction of ricochets, bullet back splatter and airborne lead.

Made in USA and available in a variety of sizes to meet a wide range of applications. The manufacturing process of combining high pressure and a weather resistant high tech polymer binder allows for an extremely dense & consistent rubber panel. Ricochet testing was done by an Independent Testing Agency that confirmed that they will absorb all 9mm Luger 124 grain, FMJ rounds at an angle greater than 5 degrees and 5.56 x 45mm 62 grain, M855 ball rounds at an angle greater than 10 degrees.

Note:

Custom sizes also available. Please contact us for a quote.

Minimum order qty: Depends on the product type.

Specifications

- The tensile strength: 950-1150 psi

- Ultimate elongation: 210-300%

- 100% modulus: 350-400psi

- The coefficient of friction: 1.2-1.25 static

- UV exposure

- ATSM D 925-88(00) 72 has ten inches below 275W

- RS UV bulb: tensile strength 5.9 % change

- Elongation 6.7% change

- Safe Live Fire Environment

- Stopping Ricochet & Self-Healing

- Ballistic Control

Datasheet

Cutting Ballistic Rubber

CUTTING RUBBER

Before diving into cutting techniques, it’s crucial to understand high density rubber’s properties. This material is designed to be durable, dense, and elastic to effectively capture bullets and reduce ricochet. These same properties, however, make it challenging to cut.

PREFERRED CUTTING METHOD: HIGH TORQUE VERTICAL BAND SAW

- Tool Selection: The ideal tool for cutting rubber blocks is a variable speed, high torque vertical band saw. The variable speed allows you to adjust the blade’s speed based on the rubber’s density and thickness. Some Oscillating saws will work too.

- Blade Choice: A serrated blade or a meat blade is preferred for this task. These blades are designed to handle tough materials and can easily slice through the dense rubber without getting stuck.

- Setting Up the Saw: Secure the rubber block in place. Ensure it’s stable and won’t move during cutting. Adjust the band saw’s speed to a lower RPM to start, gradually increasing as needed.

- Cutting Process: Begin cutting by slowly feeding the block into the blade. Apply steady pressure but avoid forcing the rubber into the blade, as this can cause unnecessary friction and wear on the blade.

- Monitoring Friction: Keep an eye on the amount of friction generated during cutting. Excessive friction can heat the blade and the rubber, potentially causing the rubber to melt onto the blade. If this happens, stop, let the blade cool down, and clean any rubber residue off the blade.

- Safety Precautions: Always wear protective gear, including safety glasses and gloves. Ensure that the area is well-ventilated, as cutting rubber can generate fumes.

USING A WATER JET FOR PRECISION CUTTING

If you have access to a water jet cutting system, it offers an excellent alternative for slicing through ballistic rubber. Water jet cutting uses a high-pressure stream of water, sometimes mixed with an abrasive substance, to cut through various materials, including dense rubber. This method is renowned for its precision and ability to produce clean, smooth edges without generating heat, thus eliminating the risk of melting or deforming the rubber. It’s especially useful for intricate designs or patterns that would be challenging to achieve with traditional cutting tools. Additionally, water jet cutting is a non-contact method, meaning there’s less wear and tear on the cutting equipment, and it doesn’t produce harmful dust or fumes. However, it’s important to note that water jet systems can be costly and may require specialized training to operate. If available, this cutting method can greatly enhance the efficiency and quality of your work with ballistic rubber.

ALTERNATIVE METHODS FOR THINNER RUBBER

- Utility Knives: For thinner ballistic rubber blocks or sheets, a strong, sharp utility knife can be effective. This method is more labor-intensive but can be used for smaller or more intricate cuts.

- Preparing for Cutting: Mark the line where you intend to cut on the rubber. Ensure the rubber is securely fixed in place to prevent it from moving.

- Cutting Technique: Using a utility knife, apply steady pressure and make a series of shallow cuts along the marked line. Gradually deepen each subsequent cut until you’ve completely sliced through the rubber. This method helps maintain control and reduces the risk of the knife slipping.

- Regular Blade Changes: Utility knife blades can dull quickly when cutting dense materials like ballistic rubber. Change blades frequently to maintain efficiency and safety.

ADDITIONAL TIPS ON CUTTING RUBBER

- Lubrication: Applying a lubricant can help reduce friction and heat build-up. Use a lubricant that is safe for both the blade and the rubber.

- Regular Blade Maintenance: Regularly check your saw blade for signs of wear and tear. A dull blade can make the cutting process more difficult and dangerous.

- Customized Cuts: For complex shapes or large quantities, consider using a professional cutting service equipped with more advanced machinery, such as CNC (Computer Numerical Control) or Waterjet machines.

- Disposal of Offcuts: Properly dispose of or recycle rubber offcuts. Consult local regulations for appropriate disposal methods.

FINAL THOUGHTS ON CUTTING RUBBER

Cutting ballistic rubber blocks requires the right tools, techniques, and safety measures. While a high torque vertical band saw with a serrated blade is the preferred method for thicker blocks, utility knives can be effective for thinner materials. Regardless of the method, always prioritize safety, maintain your tools, and approach the task with patience and precision. With these guidelines, you can achieve clean and efficient cuts for your ballistic rubber needs.